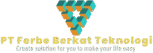

Background

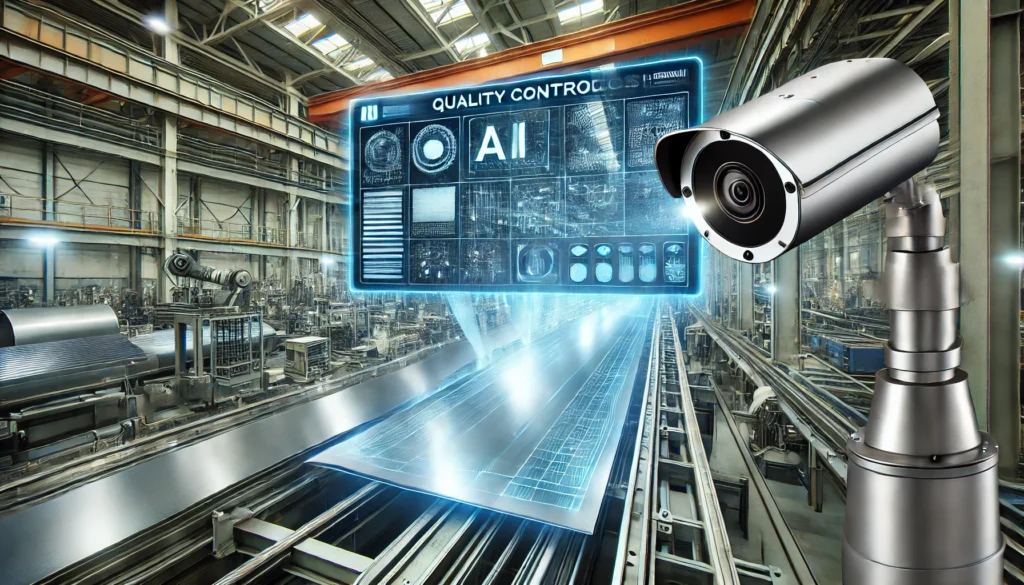

In the metal and steel industry, maintaining high-quality standards is non-negotiable. Product durability and compliance with strict regulations are paramount, but traditional quality control methods, such as manual inspections, often fail to detect micro-defects and inconsistencies. This leads to increased waste, costly rework, and potential safety hazards. To address these challenges, a leading steel manufacturer can implement an AI-powered vision system equipped with high-resolution macro cameras to automate defect detection and optimize quality control processes.

The Challenge

The company faced several critical quality control issues:

- Micro-Defects in Metal Sheets: Small cracks, scratches, and surface irregularities were nearly impossible to detect with the naked eye or standard cameras.

- Inconsistent Thickness and Dimensions: Variations in material thickness and structural integrity compromised product performance.

- High Waste and Rework Costs: Defects often went unnoticed until later production stages, resulting in excessive material waste and operational expenses.

- Slow Inspection Processes: Manual inspections were time-consuming, prone to error, and could potentially create bottlenecks in production lines, slowing down production and ultimately slowing down revenue.

These challenges weren’t just costing money—they were threatening the company’s reputation and ability to meet industry standards.

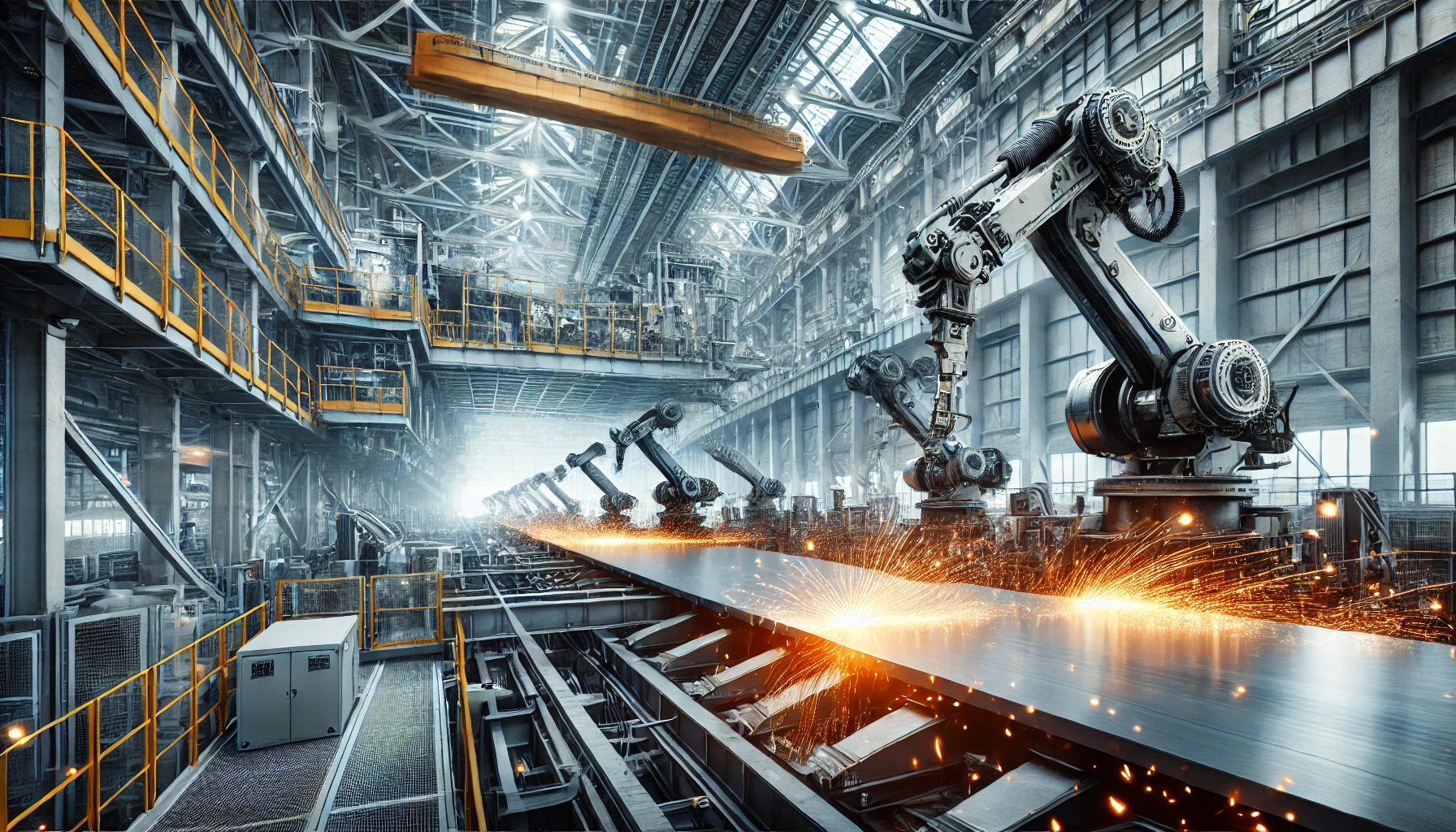

The Solution

The company deployed an AI-powered vision system with high-resolution macro cameras and advanced machine vision capabilities. Key features included:

- Automated Defect Detection: AI algorithms analyzed metal surfaces in real time, identifying even the smallest cracks, scratches, and irregularities with pinpoint accuracy.

- Precision Measurement Tools: The system measured thickness, dimensions, and alignment with micron-level precision, ensuring compliance with strict industry standards.

- Real-Time Alerts & Reporting: Any detected anomalies triggered instant alerts, enabling immediate corrective actions and minimizing defective output.

- Predictive Analytics: AI monitored production trends and predicted potential quality issues, preventing defects before they could occur.

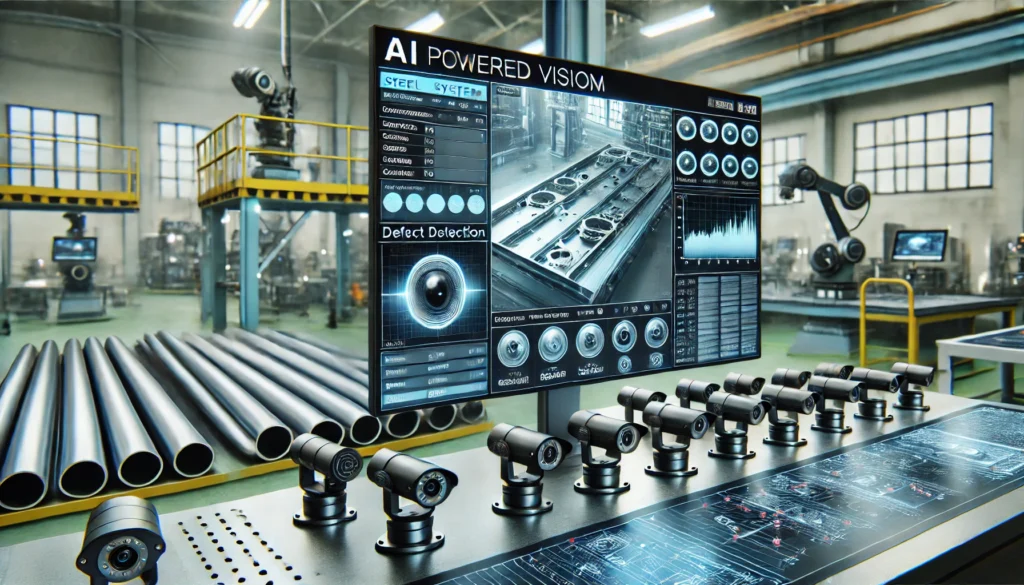

The Results

The impact will be felt on several factors:

- Reduction in Defective Products: Automated monitoring drastically improved defect detection rates, ensuring higher-quality output.

- Decrease in Waste & Rework Costs: Early-stage defect identification slashed material waste and eliminated unnecessary rework.

- Faster Inspections, Smoother Operations: Real-time AI analysis accelerated quality checks, keeping production lines running efficiently.

- Stronger Regulatory Compliance: The company consistently met stringent industry standards, boosting its reputation and market position.

Conclusion

By integrating AI-powered vision systems with high-resolution macro cameras, the steel manufacturer didn’t just solve problems—it set a new standard for excellence. The system enhanced defect detection, reduced waste, and streamlined operations, proving that AI-driven solutions are the future of quality assurance in the metal and steel industry.

Precision matters. Don’t let defects compromise your products. Embrace AI-powered vision systems and elevate your quality control to the next level.